Introduction

Every year, millions of workers face preventable injuries and illnesses in the United States. The good news? When organizations invest in comprehensive safety and health programs that employees can access at work, they see measurable benefits.

The OSHA data demonstrate that companies that implement structured safety training programs alongside safety resources achieve 30-50% reductions in workplace injuries.

The guide explains the resources workers need while demonstrating how technology streamlines their compliance needs. From personal protective equipment to health and safety management software, we’ll explain everything that keeps teams safe and compliant.

Employers, co-workers, Safety Data Sheets (SDSs), and training materials are included as workplace safety and health resources, while blogs are not included.

Understanding Workplace Safety Resources

Safety and health resources provide organizations with tools and equipment and training systems that safeguard workers from work-related hazards.

Organizations are required to use ISO 45001 standards to identify workplace hazards and implement specific safety measures. The framework requires organizations first to assess risks and then implement control measures before they can monitor the results.

The Three Categories of Safety Resources

| Category | Examples | Purpose |

| Physical Resources | PPE, guards, signage, emergency equipment | Directly prevent injuries |

| Administrative Resources | Training, procedures, safety committees | Create a safety culture |

| Digital Resources | Compliance management software, dashboards, and incident logs | Monitor and track compliance |

Personal Protective Equipment (PPE)

PPE (Personal Protective Equipment) serves as the primary defense system that protects workers from hazards. Engineers must eliminate all dangers before they can use PPE as their last safety measure.

Common PPE Types

Head Eye Hand Protection

- Hard hats, safety glasses, and chemical-resistant gloves

- Steel-toed boots to protect against crushing hazards

- High-visibility vests for traffic zones

Body Respiratory Protection

- Heat-resistant clothing and aprons

- Dust masks and respirators to protect against gas and vapor exposure

- Self-contained breathing apparatus SCBA systems for confined spaces

The Hierarchy of Controls

- Elimination – Remove the hazard completely

- Substitution – Replace with something safer

- Engineering Controls – Install equipment or barriers

- Administrative Controls – Change work procedures

- PPE – Protect the worker (last resort)

PPE usage protects workers from hazards, but the protection only provides partial safety.

Engineering Controls

Engineering controls separate workers from hazardous areas, which creates safer workplaces compared to using personal protective equipment.

Common Controls:

- Machine guards and interlocks on moving machinery

- Ventilation systems, which include exhaust fans and HEPA filtration

- Fall protection systems, which include guardrails and safety nets, and harnesses

- Ergonomic equipment, which provides for adjustable workstations and lifting carts

Administrative Controls and Procedures

Administrative controls change work execution through their established procedures and operational framework.

Key components include:

- Written procedures for high-risk tasks that require annual updates

- Hazard assessments, which identify potential risks before incidents occur

- Safety committees, which consist of management and workers, conduct discussions and implement corrective measures

- Clear responsibilities for workers and supervisors

Training and Education

Organizations use training programs as their method to change employee behavior into actual performance. The absence of training prevents workers from using their high-quality equipment.

Essential Training Types:

- Initial orientation: Hazards, emergency procedures, reporting methods

- Job-specific: Machinery operation, chemical handling, proper PPE use

- Refresher training: Annual reviews, new equipment, and incident follow-ups

- Specialized: First aid, fire safety, forklift operation, HAZMAT handling

Pro Tip: Organizations should implement best compliance management software to monitor their staff’s training progress and ensure they meet certification requirements

Emergency Response Resources

Fire Safety Equipment

- Fire extinguishers and fire blankets are in all areas of the facility.

- Evacuation routes and exit signs for emergencies.

- Equipped with emergency lighting systems and alarm systems.

Medical Equipment

- First aid kits in accessible locations

- Automated external defibrillators (AEDs)

- Eye wash stations and safety showers

- First aid-trained personnel on each shift

Emergency Planning

- Evacuation drills every three months

- Established protocols to handle emergencies, which include fire incidents, chemical spills, and medical emergencies.

- Designated areas where people must gather during emergencies.

- Conducts routine evaluations of incident response procedures.

Health and Safety Signage

Visual communication systems provide safety warnings that protect workers from dangerous situations.

Types of Signs:

- Hazard warnings: Chemical symbols, machinery danger, pinch points

- Directional signs: Emergency exits, first aid location, fire extinguishers

- Prohibition signs: “Do Not Operate,” “No Smoking,” “Authorized Only.”

Health and Safety Management Software: The Digital Resource

Health and safety management software and compliance management software are crucial in the modern workplace for safety management.

Key Software Functions

Real-Time Hazard Logging

- Workers use mobile devices to report hazards in real time

- Supervisors establish corrective measures

- A database allows users to search and retrieve information, which helps them resolve problems that occur repeatedly.

Training and Certification Tracking

- Sends automated alerts when certifications approach their expiration date

- Keeps records of all completed training programs used for audit purposes

- Reports demonstrate compliance by displaying the current status of training programs

Inspection and Audit Management

- Digital checklists eliminate the need for paper documentation

- Enables users to collect evidence through photos and videos

- Generates reports to document all instances of non-compliance

Incident and Injury Tracking

- Allows users to report incidents from a central location

- Provides tools for performing root cause investigations

- Will enable users to identify patterns that exist across different geographic areas

How Jadian Software Helps

Jadian‘s health and safety management software helps organizations achieve compliance through its following features:

- Allows you to create workflows that match your specific operational requirements

- Provides users with the ability to track operations across different locations

- Field personnel can access the system from their mobile devices

- Sends automatic alerts to users about approaching deadline dates

- Produces detailed audit reports that show all system activities

Jadian users experience reduced administrative work, which allows them to focus on safety measures.

Occupational Health and Safety Standards

The established standards provide reliable security measures that maintain their effectiveness throughout time.

Key Standards:

ISO 45001: The international standard mandates organizations to identify hazards through active processes while engaging workers for ongoing performance assessments. This applies to all manufacturing and construction activities, healthcare facilities, and service operations.

OSHA Regulations (USA): Require organizations to create safe work environments through proper hazard communication, employee training, and recordkeeping practices while establishing specific requirements for dangerous work sectors.

Creating an Effective Health and Safety Program

The process of developing an effective health and safety program requires organizations to transform their positive intentions into ongoing daily operations.

5 Essential Steps:

- Assess Hazards: Walk the facility, interview workers, and review incident history

- Implement Physical Resources: Acquire PPE, install engineering controls, and set up first aid stations

- Develop Procedures: Create SOPs for high-risk tasks, document assessments, and establish emergency plans

- Train Employees: Conduct orientation, job-specific training, refresher sessions

- Use Software: Deploy compliance management software for record-keeping, training tracking, and audit documentation

Safety becomes an ongoing business function when you consistently execute these five steps. Your program will reduce incidents while establishing trust with workers and streamlining compliance management.

Common Mistakes Organizations Make

Even with the best of intentions, many organizations fall into the same safety pitfalls that can quietly undermine their programs. It is much easier to correct course and build a strong safety culture when these pitfalls are recognized early on.

Here are five common mistakes organizations make:

Mistake 1: PPE-Only Strategy

PPE serves as the final protective measure, which should not function as a complete protection method. Fix hazards first.

Mistake 2: Training Without Follow-Up

One-time training doesn’t stick. Use refresher sessions and supervisor reinforcement.

Mistake 3: Ignoring Worker Input

Workers see hazards that managers miss. Use committees and incident reporting systems.

Mistake 4: No Documentation

If there exists no documentation, then nothing occurred for legal purposes. Compliance management software ensures evidence of due diligence.

Mistake 5: Inconsistent Enforcement

If enforcement varies, safety becomes optional. We need to treat all employees with the same level of enforcement.

Building a Sustainable Safety Culture

Resources alone don’t prevent incidents. Organizational values serve as their primary defense mechanism.

Strong Culture Elements:

- Leadership commitment: Management demonstrates safety support through budget allocation and adherence to operational rules in support of their safety commitments.

- Worker participation: Employees contribute to safety efforts through their ongoing hazard reporting, active committee participation, and receive recognition for their achievements.

- Continuous improvement: Organizations conduct annual performance evaluations together with trend analysis to create updated operational procedures.

- Communication: The Organization needs to share incident data while explaining safety rules and celebrating near-miss reporting.

Frequently Asked Questions

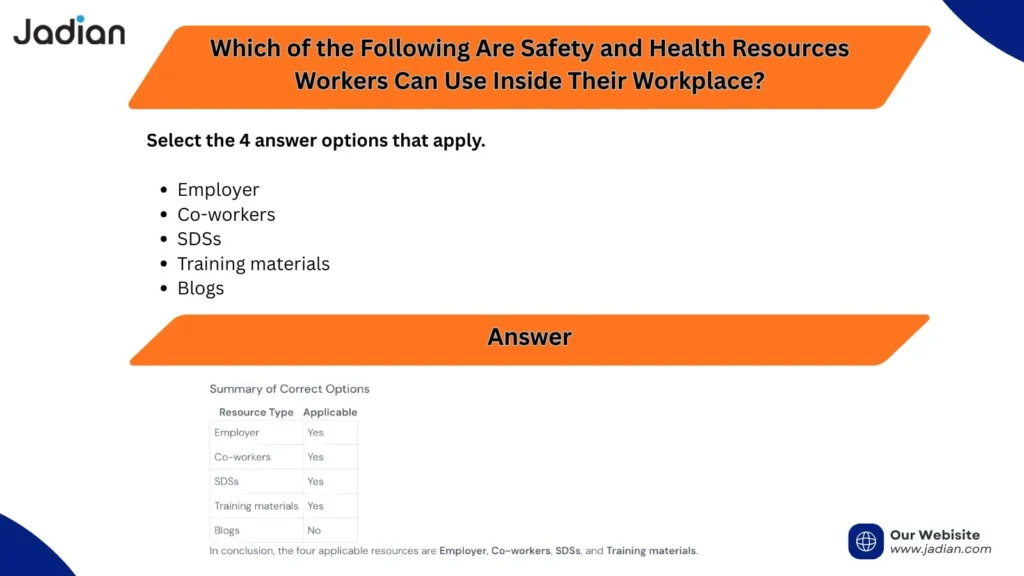

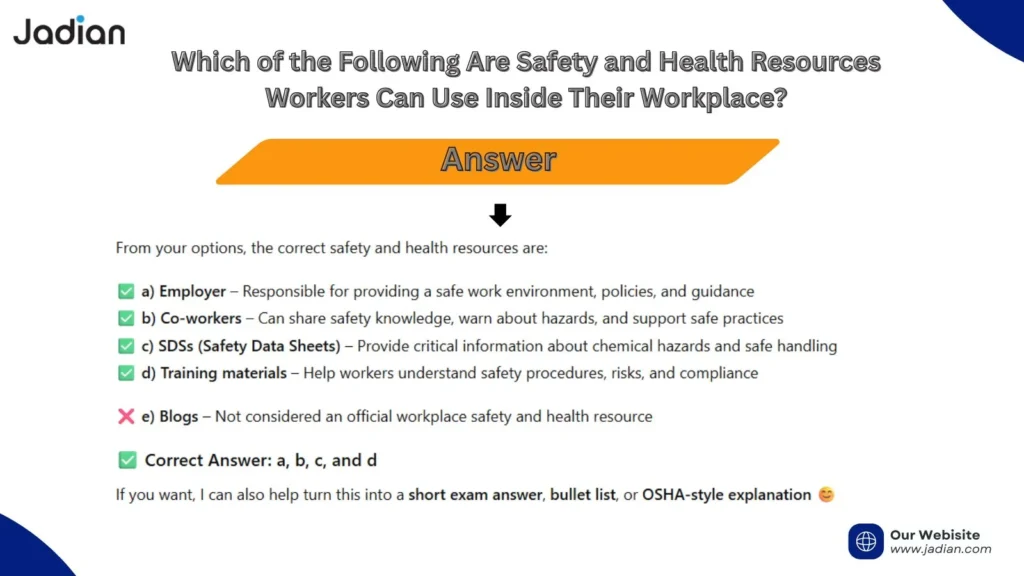

Q: Which of the following are safety and health resources workers can use inside their workplace?

A: Some of the safety and health resources that workers can utilize include safety guards, safety signs, emergency response equipment, and personal protective equipment. These include administrative procedures, staff training, health and safety software, and first-aid supplies, such as automated external defibrillators, based on workplace risk.

From your options, the correct safety and health resources are:

✅ a) Employer – Responsible for providing a safe work environment, policies, and guidance

✅ b) Co-workers – Can share safety knowledge, warn about hazards, and support safe practices

✅ c) SDSs (Safety Data Sheets) – Provide critical information about chemical hazards and safe handling

✅ d) Training materials – Help workers understand safety procedures, risks, and compliance

❌ e) Blogs – Not considered an official workplace safety and health resource

✅ Correct Answer: a, b, c, and d

If you want, I can also help turn this into a short exam answer, bullet list, or OSHA-style explanation

Q: How does compliance management software improve workplace safety?

A: Compliance management software maintains safety standards through its ability to establish responsibility with documentation, workflow automation, centralized hazard information, training deadline management, audit report creation, and systemic issue detection through trend analysis.

Q: How often should workplace inspections occur?

A: All workplaces need to conduct at least one monthly inspection. All high-risk areas require either daily or weekly inspection schedules. The organization needs to conduct inspections immediately after incidents and when new equipment arrives.

Q: What should workers do if they find an unsafe condition?

A: Workers need to exit hazardous areas and report dangerous situations to their supervisors. In contrast, they need to document all issues and track the corrective action without any fear of retaliation.

Q: How can small businesses implement these resources?

A: Begin with free hazard identification software, establish simple PPE, develop easy-to-understand written procedures, assign safety representatives, take advantage of inexpensive software, invest based on data from incidents, and utilize free government training resources.

Bottom Line

Resources for safety and health at work are not a choice but a necessity. When organizations offer resources and create a culture that prioritizes safety, the result is a reduction in incidents, increased productivity, and employees leaving the workplace in good health.

The best organizations seamlessly integrate:

- Physical resources (PPE, equipment, signage)

- Administrative resources (training, procedures, committees)

- Digital resources (health and safety management software for tracking and compliance)

Begin with your current resources. The process of enhancement requires you to find deficiencies first and then distribute funds before you select superior safety solutions for your personnel.

Your workers’ safety is worth the effort.