Unexpected breakdowns in field service result in urgent repairs and higher costs. However, the IoT field service changes this by turning connected devices into tools that spot issues early. With this, teams can find problems before they get worse and send help right when it’s needed. This works by sending a steady flow of sensor data into management software.

As a result, companies can take a more proactive approach, ensuring that operations run smoothly and assets operate at their best.

What Is IoT Field Service?

IoT field service uses smart devices, sensors, and software to keep track of the equipment and streamline tasks. These systems instantly relay data to a central hub. With this, teams no longer have to wait for complaints or manually inspect items. It also helps service teams identify problems early and resolve them more quickly.

Today’s IoT field service management tools work with these systems to turn basic machine data into helpful information. This change lets organizations move from reacting to problems to predicting and stopping them before they occur.

How IoT Transforms Traditional Field Service Models

IoT in field service management links smart devices, data systems, and field service teams.

For example, sensors in equipment collect live data, such as temperature, shaking, pressure, or the duration of use. This data goes to the cloud, where analytics and business rules check the health of the assets.

Field service IoT systems use the information to take action. These actions include sending alerts, starting work orders, or suggesting maintenance before something breaks. The main goal is automation: making sure the right service happens at the right time with as little manual work as possible.

Traditional field service relies on scheduled maintenance or waiting for customers to report breakdowns. The Internet of Things field service changes this by using continuous monitoring and predictive tools.

It prevents unnecessary trips, boosts first-time fix rates, and lowers downtime. Over time, companies shift from reacting to problems to managing service more strategically.

Examples of IoT-Enabled Assets in the Field

Many industries utilize IoT in field service management to ensure their equipment operates efficiently. Here are some examples of IoT-enabled assets used in the field:

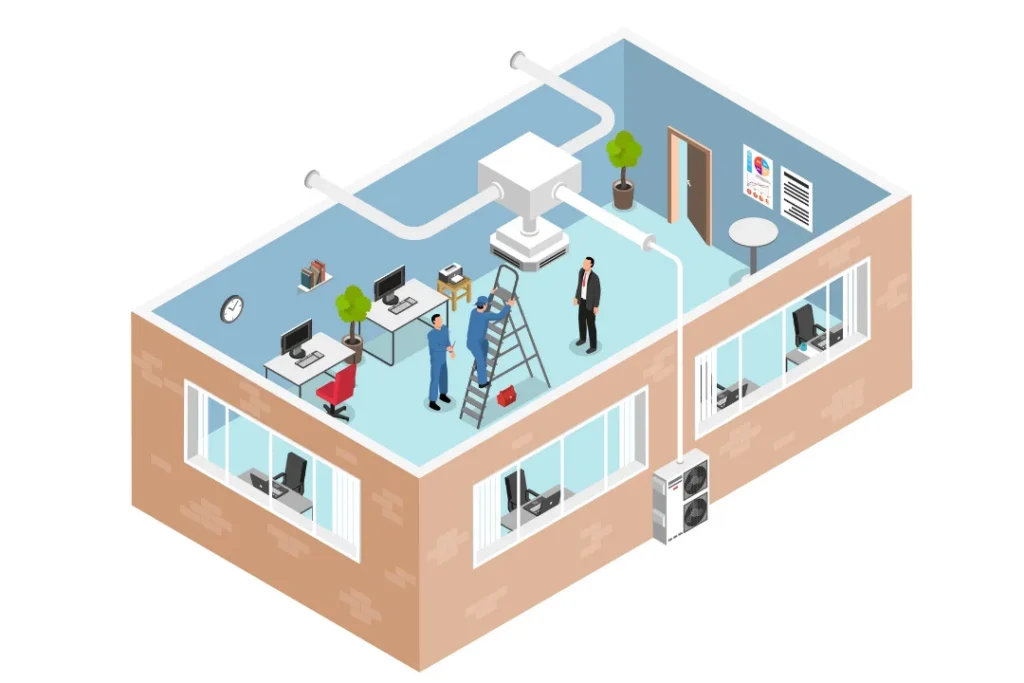

Smart HVAC, Plumbing & Electrical Systems

IoT sensors in heating, ventilation, and air conditioning (HVAC) units can track airflow, temperature changes, and filter condition. These devices can send automatic alerts to service teams before performance drops or failures happen. This is a typical example of how data from IoT devices can help direct service actions.

Smart thermostats and sensor networks in HVAC systems share performance data and can ask for maintenance before anything breaks down.

Automated Machinery Monitoring

Sensors on industrial machines detect unusual activity, error codes, or patterns that could signal a future problem. This data is sent to service systems, which create work orders to address issues before they get worse.

When sensors pick up unusual vibrations or temperature shifts, field service teams can plan repairs early and prevent major breakdowns.

Smart Metering and Utilities Monitoring

The platform connects to equipment such as electricity and water meters to quickly report problems or power cuts. Once a warning comes in, workers are sent out immediately. This helps reduce delays and keeps everything in line with the rules.

For example, smart grid sensors find outages and send repair teams the location and severity details automatically.

How IoT Field Service Works (Architecture & Data Flow)

With IoT, data now flows constantly from field equipment into software that helps make smart service decisions. This approach leads to a proactive, automated, and data-driven field service model using the Internet of Things. Here is how it works:

Connected Sensors and Smart Assets

To begin, you install connected sensors and smart devices on equipment such as machines, HVAC systems, vehicles, or infrastructure. These sensors monitor temperature, vibration, pressure, equipment usage time, and error codes.

A connected field service IoT system helps your equipment work together. It sends live updates and quickly alerts you to issues like damage or potential breakdowns.

Data Transmission to the Cloud Platform

The cloud platform forms the heart of the system. Sensor data travels from equipment through different networks to reach the platform. Here, information from thousands or even millions of devices in remote locations is gathered and stored.

This step is vital for IoT service management, as it enables users to monitor devices from anywhere. It also helps data reach analysis tools and service management systems quickly, so teams can respond faster.

Analytics, Rules Engines, and Failure Detection

When data is stored in the cloud, smart software and clear rules help keep things running well. These tools check limits, patterns, and past results to spot anything unusual or signs of possible problems.

Whenever there is sudden movement or a spike in temperature occurs, the system instantly alerts you with a warning. In more advanced IoT setups, machine learning models can predict failure days or even weeks ahead. This way, service teams can fix problems before they lead to outages.

Automatic Work Order Creation in the Field Service System

When the system detects a possible problem, it automatically takes action. Most often, it creates a job request in the field service management (FSM) platform. The work order includes asset details, fault codes, location data, and service history, all of which are added automatically without manual input.

This automation is a major advantage of connected field service IoT.

Technician Dispatch and Real-Time Service Execution

The FSM system schedules and sends the best technician for the job. It considers their skills, availability, location, and needed parts. Technicians get the work order on their mobile devices. This includes all the details they need, such as asset data and diagnostic insights.

Technicians can update the job status as they work. Once the equipment is fixed, it continues to send updates to confirm that the problem is resolved. This closed-loop process completes the IoT field service cycle by turning sensor data into actions, solutions, and ongoing improvements.

Measuring ROI of IoT in Field Service (KPIs)

It’s important to measure return on investment when starting field service IoT projects. Connecting assets and automating service tasks helps organizations see real improvements in cost, efficiency, and customer satisfaction. With IoT, these benefits become clear because sensor data links directly to service results and key performance indicators.

Below are some of the KPIs to watch for when measuring return on investment in IoT field service management.

Reduced Truck Rolls and Site Visits

One of the main benefits of field service IoT is that it reduces unnecessary truck rolls. Remote monitoring enables service teams to determine whether a problem requires an on-site visit or can be resolved remotely. Many organizations see 10% to 30% fewer truck rolls after using IoT-enabled monitoring.

Increased First-Time Fix Rate

When technicians have up-to-date information about equipment and its problems, they can arrive with the right tools, parts, and details. This makes it more likely they will fix the problem on their first visit.

Companies that use smart devices in managing their field work often see their first-time fix rates go up by 5% to 15%.

Lower Asset Downtime

Field service IoT acts like an early warning system, catching issues before they turn into costly breakdowns. For equipment-heavy industries, this means machines spend 20% to 40% less time out of action due to surprise failures. This helps customers keep important equipment running and avoid costly problems.

Improved Technician Productivity

IoT service management automates alerts, work order creation, and scheduling. This cuts down on administrative tasks and helps send technicians where they are needed most. Technicians can focus less on diagnosing issues and more on making repairs.

Using IoT in field service often makes work 10% to 25% more productive. This happens because jobs are planned better, workers need to go back less often, and routes are more efficient.

Cost Savings from Preventive Maintenance

Preventive and condition-based maintenance helps organizations avoid expensive emergency repairs and extend the life of their equipment. Data from connected devices allows companies to schedule maintenance based on usage and condition, rather than sticking to a timetable.

Teams using IoT for field service management often save 15% to 30% on maintenance costs. They also benefit from more reliable assets and longer equipment lifespans.

IoT and FSM Software Integration Checklist

Implementing Internet of Things field service is more than just installing sensors or connecting devices. Organizations must ensure that their IoT systems, field service management software, and frontline teams all work seamlessly together.

This checklist covers the main integration points to review before you start.

Device and Sensor Compatibility

First, make sure your devices and sensors work with your current equipment and settings. Sensors must collect the correct data and function effectively in real-world conditions. In a connected field service IoT system, make sure your devices can grow with your needs and handle firmware updates.

IoT Platform and Cloud Infrastructure

Pick an IoT platform that securely collects and stores data from all your connected devices. It should let you view data in real time, control your devices, and connect easily with your other systems.

When using IoT for field service, it is important to have cloud solutions that can scale and remain reliable. This is especially true if you manage many devices in different places.

Field Service Management Software Integration

Your FSM software should receive IoT signals and turn them into service tasks you can act on. It should create work orders, add asset data, and send alerts automatically. This way, you do not have to do these steps by hand.

A strong IoT field service system helps your team act on information immediately. This way, they do not have to wait for issues to arise.

Data Mapping, Analytics, and Automation Rules

Consider how you can link IoT data smoothly with service events in your field service system. Here, you define boundaries, craft smart alert rules, and decide which scenarios should trigger work orders, notifications, or extra care.

A clear data map helps you reduce alert overload. It helps your IoT field service projects stay focused on the most important moments.

Security, Privacy, and Compliance Considerations

Security is important at every level of IoT and FSM systems. This includes making sure devices are genuine, protecting sensitive data, and stopping unauthorized access. Companies using connected field service IoT need to follow data privacy laws and local regulations to avoid problems.

Technician Adoption and Change Management

Even the best technology is not effective if people do not use it. Technicians do well when they are trained to trust IoT alerts, understand equipment data, and use FSM mobile tools with confidence.

The most successful IoT field service programs focus on change management. They clearly explain the benefits, make workflows easier, and help technicians work smarter instead of harder.

Conclusion: Turning Connected Assets Into Service Intelligence

IoT field service is changing the way organizations deliver, manage, and grow their service operations. By connecting equipment and automating workflows, companies can shift from just fixing problems to predicting and preventing them. Machines that once operated on their own now share real-time information, helping teams make better decisions during the service process.

With today’s IoT service management platforms, connected equipment does more than just let you know when something is wrong. These systems can initiate quick fixes, assist workers in their tasks, and improve the customer experience. Companies embracing this approach gain sharper insight into their equipment’s performance and unlock smoother, more efficient operations.

With customers demanding faster and more dependable service, connected equipment has become vital for gathering real-time insights. IoT field service empowers organizations to craft proactive, data-driven strategies that deliver immediate, tangible results.

This prepares them to embrace the future, where smarter, more innovative service delivery becomes the new standard.

FAQs

What is IoT field service?

The IoT field service utilizes connected sensors and devices to monitor assets in real-time and automate service tasks. This approach helps companies maintain equipment proactively, solve problems faster, and work more efficiently.

How does IoT in field service management work?

Sensors on the equipment gather data and send it to a cloud platform. Analytics tools identify issues, send alerts, and generate work orders within the field service system. This helps technicians get dispatched quickly and makes service run more smoothly.

What are the benefits of using IoT for field service?

The main benefits are:

- Less downtime

- More first-time fixes

- Fewer trips for technicians

- Better productivity

- Lower costs

What types of assets can be monitored with IoT field service?

IoT can track industrial machines, HVAC systems, vehicles, medical devices, utility networks, and other important equipment. Any device with sensors can use predictive service to improve performance.

How do I measure ROI from IoT-enabled field service?

Key performance indicators (KPIs) are fewer truck rolls, higher first-time fix rates, less asset downtime, improved technician productivity, and lower maintenance costs.