Food allergens pose significant concerns in the food manufacturing industry. Effective allergen control safeguards consumers and regulators and creates brand equity. Any food facility that handles allergenic ingredients must know its policies, procedures, and best practices.

The article explains the importance of managing allergens well in food manufacturing. It includes the most appropriate practices for allergen storage, how to avoid cross-contact in production, and the establishment, control, and maintenance of an effective allergen management program to maintain food safety and compliance.

What Is the Significance of Allergen Management in the Manufacture of Food?

Not only is the management of allergens in food production essential to the health and lives of allergic consumers, but it is also important to the integrity of the product and regulatory compliance.

Given that trace levels of allergens can cause life-threatening reactions, maintaining a well-organized allergen control program is not only a legal requirement but also an ethical duty for any food manufacturer.

- The effective management of allergens helps prevent cross-contact, minimize food recalls, and protect allergic consumers.

- Allergens may lead to severe reactions such as anaphylaxis.

- Trace amounts are also hazardous.

- Strict control of allergens has to be implemented by regulatory authorities.

- All food manufacturers have a legal and ethical duty to maintain a sound allergen management program.

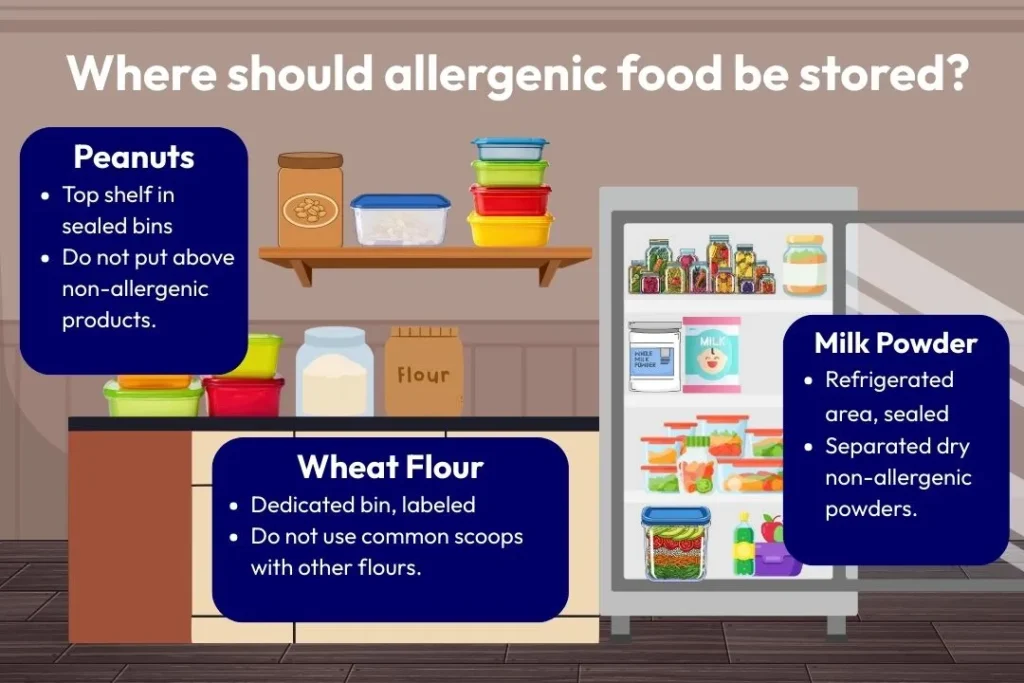

Where Should Allergenic Food Be Stored To Prevent Cross-Contact?

It is vital to store allergenic foods properly in order to avoid cross-contact. The non-allergenic foods should always be stored in an isolated place from all allergenic ingredients.

Best practices include:

- Specific storage space: Allergic food should be stored in distinct shelves, bins, or rooms.

- Physical barriers: Accidental mixing should be avoided by using containers that are labeled.

- FIFO management: Turn the product around the stock of allergens so as to prevent any contamination of expired products with the others.

- Precautionary temperature: Store according to the rules in order to preserve the integrity of the ingredients.

- Labeling and signage: Marks on allergenic areas should be conspicuously displayed to warn staff.

Example:

| Allergenic Food | Storage Recommendation | Precaution |

|---|---|---|

| Peanuts | Top shelf in sealed bins | Do not put above non-allergenic products. |

| Milk Powder | Refrigerated area, sealed | Separated from dry non-allergenic powders. |

| Wheat Flour | Dedicated bin, labeled | Do not use common scoops with other flours. |

The basis of any allergen management plan involves proper storage of the products so that risks of cross-contact can be reduced.

What Is an Allergen Management Program?

An allergen management program is a systematic framework that is used to identify, manage, and communicate allergenic ingredients in a plant.

Key elements include:

- Allergen identification: Indicating all allergenic food materials used in manufacture.

- Risk assessment: Knowledge of the location of the possible cross-contact.

- Measures of control: Avoiding accidental contamination.

- Labeling and communication: Correct declaration of allergens on packaging.

Adhering to a structured program, manufacturers reduce risks and make sure that they comply with the regulations of food allergen management.

What Should Be Done To Avoid Cross-Contact During Food Production?

Contact between allergic and non-allergenic foods brings about cross-contact. It is important to prevent it as a safety measure.

Key prevention strategies:

- Specialized equipment: Pieces of equipment such as mixers, slicers, and utensils must be allergen-specific.

- Cleaning procedures: Wash between production processes with clean methods that have been proven correct.

- Production scheduling: The allergen-free products should be made first, followed by allergens.

- Employee education: Ensure that employees are aware of the risk of allergens and management.

Periodic evaluation will make sure that the control measures against allergens are effective.

What Is an Allergen Management Policy Supposed To Consist Of?

An allergen management policy is a set of guidelines on how to manage allergens in a safe manner in your facility.

Essential components:

- Limits of allergens: Determine what ingredients must be strictly controlled.

- Roles and responsibilities: Delegate responsibilities to employees.

- Storage processes: Describe separation, labelling, and handling procedures.

- Production controls: These consist of scheduling, equipment usage, and cleaning.

- Labeling requirements: Adhere to the labeling regulations of allergen management labeling.

- Records: Record training, audits, and incidents.

An allergen management program is supported by a clear policy.

What Is the Recommended Method of Monitoring and Verification of Allergen Management?

The tracking of your policies will make sure that they are efficient and adhered to.

Methods include:

- Internal audit: Storing, labeling, and cleaning of checks.

- Environmental swabs: Identify allergen deposits in surfaces and equipment.

- Consideration of complaints: Monitor allergen customer feedback.

- Checks on documentation: Check the records to ensure that they are up to date and complete.

Confirmation supports a positive attitude to food allergen management.

Why Is the Labeling of Allergen Management Important?

Proper labeling of allergens will safeguard the consumers and fulfill the law.

Best practices for labeling:

- Obviously, provide all the allergenic ingredients.

- It should be bold or highlighted with allergens.

- Add words such as May contain traces of. in the case of cross-contact hazards.

- Label updated in case of ingredient or supplier change.

Good allergen management labelling will develop consumer confidence and minimize liability.

What Is the Way To Train Staff on Allergen Control?

The employees are central to avoiding allergen incidents. Training should be:

- Frequent and compulsory: Add on boarding and refresher.

- Practical: Show how to store, handle, and clean properly.

- Accessible: Support the learning process with the help of posters, guides, and videos.

- Tested: Have assignments or tests to verify learning.

Educated employees will ensure the efficiency of your allergen management plan in the day-to-day running of the establishment.

What Are the Problems of Allergen Management?

The control of allergens is not a simple task, but there are problems such as:

- Several allergenic ingredients: The facilities with high numbers of allergens augment the risks of cross-contact.

- Basic equipment: Equipment may not be dedicated, and it is important to ensure that it is cleaned up thoroughly.

- Supplier inconsistency: Ingredients can include undeclared allergens.

- Human error: There are errors in labeling, storage, or production.

This problem has to be dealt with through continuous quality improvement and powerful allergen control measures.

What Can Be Done To Assist in the Management of Allergies With the Help of Technology?

It is possible to simplify the allergen management programs with modern software:

- Ingredient tracking: Tracking allergen content by supplier.

- Automated labeling: Eliminate human errors.

- Inventory warnings: Warning flag allergenic inventory.

- Dashboard reports: Monitor compliance, audits, and incidents.

The implementation of technology will help lessen risk, enhance efficiency, and enhance your policy of allergen management.

What Are Cutting-Edge Techniques and Methods of Managing Allergies?

Normal food safety precautions are not sufficient. Achieving modern allergen control requires the application of advanced science, technology, and process design.

Such strategies reduce cross-contact risk, increase productivity, and develop an expanded allergen management strategy in any food production environment.

Separating on Production Lines and Zones

- Specialized production lines: More and more facilities invest in separate lines of allergenic products in order to avoid contact with allergens altogether. As an illustration, a bakery that produces nut products and nut-free products can reserve one oven and mixer for nut-free products.

- Zoning in common space: Complete segregation of lines is not always practical, so in areas where allergenic work is necessary, physical and visual separation can be used. This is in the form of color-coded floors, walls, or equipment to indicate allergen-specific areas.

- Airflow and ventilation control: Cross-contact may take place through airborne particles. Local exhaust ventilation can be installed in areas close to allergen handling to confine the dust content of allergens and avoid contamination of other manufacturing areas.

Allergen Detection and Testing in Real Time

- Rapid allergen test kits: New lateral flow devices enable manufacturers to identify traces of allergens on equipment and surfaces in a few minutes. This real-time response enhances a quick corrective response.

- ELISA and PCR tests: Enzyme-linked immunosorbent assays (ELISA) and polymerase chain reaction (PCR) are tests that are performed in the laboratory, which offer high sensitivity in the detection of allergenic protein. They are applied to do routine validation and audit.

- Surface swab programs: The procedure of systemically swabbing equipment, utensils, and surfaces of the work area should be implemented to ensure adherence to cleaning standards and confirmation of the absence of allergen residues.

Ingredient and Supplier Management

- Certified allergens suppliers: By working with certified allergens suppliers, the likelihood of hidden allergens making it through the production process is minimized.

- Supplier audits: It conducts regular audits to ensure the suppliers adhere to strict allergen control and labeling procedures.

- Traceability systems: Superior tracking systems are those in which the presence of allergens is checked since the receipt of raw materials up to the finished product, and transparency throughout the supply chain.

Complex Labeling and Communication Tactics

- Dynamic allergen labeling: Some companies use systems that automatically maintain the information about the allergens in case of any change in the ingredients or suppliers. This minimizes the possibility of wrongful labeling.

- QR code labeling: Packaging may contain QR codes that refer to comprehensive allergen information, such as processing procedures, cross-contamination risks, and precautions.

- Multilingual allergen labeling: This is especially applicable when distributing the product globally by labeling it in different languages so that the consumer is better positioned to understand the content of the packaging.

Industry 4.0 and Automation Solutions

- Automated dispensing systems: Human contact and risk of cross-contamination are minimized by using machines that dispense accurate amounts of allergenic ingredients.

- Robotic cleaning systems: State-of-the-art robots are able to clean the equipment and work areas with confirmed allergen elimination measures, and they minimize human error.

- Predictive analytics: Software can forecast high-risk production conditions of allergen contamination on the basis of past data, ingredient utilization, and production plans.

Constant Employee Participation and Culture Development

- Behavioral reinforcement: In addition to training, a culture of allergen awareness should be encouraged as a way of ensuring that employees stick to the procedures. Methods encompass recognition of the behaviour of compliance and peer monitoring systems.

- Simulated allergen contamination training: This is the scenario training using scenarios of allergen contamination to teach the staff how to react to such an event.

E.g., finding and isolating a spill or managing a substitution of an ingredient that just occurred.

- Cross-functional coordination: The presence of QA, production, supply chain, and R&D teams would make sure that allergen control becomes an integral part of all the departments and not a solitary part within the departmental scope.

Association With Food Safety Systems at Large

- HACCP integration: Allergen management can be integrated into the current HACCP ( Hazard Analysis and Critical Control Points ) plans. Allergens are classified as critical hazards having specific CCPs (Critical Control Points).

- Compliance with ISO 22000: Implementing allergen management into the ISO 22000 food safety management systems provides a solution to the world regarding risk evaluation, records, and corrective measures.

- On-site digital records and dashboards: Multipurpose digital interfaces can be used to monitor performance, audit trails, and real-time data to monitor the effectiveness of allergen control throughout the facility.

Successful Allergens Management Innovation Case Studies

- Bakery example: A multinational bakery conducted a study introducing specific lines, fast test kits, and color-coded zones, resulting in a 90% reduction in allergen incidents. There was almost no cross-contamination, and labeling accuracy became better.

- Beverage manufacturer case study: A beverage company used automated dosing and dynamic labeling to be able to use the same line with different flavours containing many allergens without much risk.

- Ready-to-eat meals: A meal prep business incorporates allergen labels featured in QR codes to offer real-time information to its consumers and inspectors, increasing levels of trust and transparency.

The Advantages of Advanced Allergen Management

- Improved consumer safety: Minimizes accidental exposure to allergens and anaphylactic reactions.

- Regulatory compliance: Assists in compliance with international labeling and control regulations on allergens.

- Economy of operations: Technologically backed processes eliminate human errors and wastages.

- Brand reputation: Shows a positive effort to ensure food safety, which develops consumer trust.

- Risk mitigation: Reduces the possible recalls, liability, and financial losses.

Trends in Allergen Management in the Future

- Smart packaging: Finished product sensors that detect allergens could offer a higher level of protection.

- Risk assessment by AI: AI can estimate the occurrence of allergens in complicated production conditions.

- Blockchain ingredient traceability: Provides ingredient traceability of allergens along the supply chain to be transparent and ready to recall.

- Consumer interaction tools: Smart devices and mobile applications enable consumers to scan and confirm the presence of allergens in real-time.

Future-oriented strategies and innovations take allergen management further beyond a compliance obligation to a competitive edge.

Investing in modern technology, optimization of the processes, and culture development, the manufacturers will have an opportunity to develop safer products, improve operational efficiency, and build consumer confidence.

What Is the Measure and Improvement of the Efficacy of an Allergen Management Program?

The efficiency of an appropriate allergen management program is as good as its practical performance. Performance measurement and improvement are done to ensure that policies, training, and technology are converted into the production floor safe practices.

Set Up Key Performance Indicators (KPIs)

- Allergen incident rate: Monitor the error rates of cross-contact or allergen labeling mistakes over time.

- Cleaning validation success: Determine the frequency with which the cleaning protocols can remove the residues of allergens.

- Completion rate of training: Keep track of how many staff have attended the required allergen control training.

- Label accuracy: Test accuracy of allergen declarations made on finished products.

The application of these KPIs will offer a measurable means of evaluating the performance of the allergen management plan to determine whether it is working as planned.

Do Internal Audits on a Regular Basis

In-house auditing assesses adherence to procedures and identifies opportunities for improvement. They should cover:

- Storing facilities, whereby there is a separation of allergenic and non-allergenic foods.

- Cleaning of equipment to confirm that there is no cross-contact.

- Proper labeling and packaging of products with allergens.

Audits must be documented, and the results of the audit channeled into corrective action plans. Periodical re-auditing can be used to detect trends and recurrent problems.

Use Customer Comments and Criticisms

Following up on customer feedback will provide information on the effectiveness in the real world. Complaints related to allergens, whether labeling, contamination, or a misconception about their presence, must be examined. Complaint trends will help to reveal the flaws in your program and make necessary corrections.

Scientifically Verify Cleaning and Production

- Swab testing: Trace residues of allergens on equipment, surfaces, and utensils may be detected using regular environmental swabs.

- Laboratory testing: ELISA or PCR tests can prove the existence or absence of allergenic proteins, which is objective evidence of cleaning efficacy.

- Process review: Reevaluate production sequences to make products free of allergens before those containing allergens.

Scientific validation assures your compliance with the allergen control measures and helps with compliance documentation.

Adopt the Cycles of Improvement

- Feedback loop: Based on KPI outcomes, audit, and consumer complaints, revise operations, train new staff, or change equipment use.

- Staff engagement: The employees should be encouraged to report possible risks, propose improvements, and be involved in safety culture programs.

- Technology implementation: Revise the software, nomenclature, or automated monitoring devices according to monitored performance gaps.

The constant development makes the management of allergens proactive as opposed to reactive, reducing the incidence of such cases.

Industry Cooperation and Benchmarking

The best practices can be identified through comparison of your allergen management program with your industry peers or by joining networks of professionals. By exchanging thoughts on new inventions, testing processes, or process efficiencies, you can take your program to a level that is higher than the compliance mandates.

Advantages of a Measurement of Effectiveness

- Increased consumer safety: Early identification of the breaches minimizes the risk of cross-contact.

- Regulatory assurance: There is evidence-based backing of inspections and audits.

- Operational excellence: Removing inefficiencies enhances workflow, minimizes waste, and unnecessary recalls, which are costly.

- Accountability culture: Allergen management is tracked and appreciated, a practice that helps to strengthen compliance with procedures.

Manufacturers can achieve this by constantly reviewing and refining their allergen management program to ensure that protocols can be applied in reality for safety.

This solution changes the stagnant set of rules that are in place to control allergens to a dynamic method that is able to adapt to changing production issues, consumer demands, and regulatory mandates.

FAQs

Q1: What is the distinction between allergenic and non-allergenic food?

A: Allergenic foods are the ones that usually cause a response, such as peanuts or shellfish. Foods that are not harmful produce low levels of allergy, such as rice or most fruits.

Q2: What should be the frequency of allergen training?

A: At least on a yearly basis, and at the onboarding as well as when there are changes in processes or ingredients.

Q3: Is it possible to call off allergen cross-contact?

A: It is difficult to reduce 100 percent of the risk, but unless it is done, strict separation, cleaning, and labeling procedures reduce it to a minimum.

Q4: What is to be done in the event of allergen occurrence?

A: Recording of the incident, informing the impacted parties, reviewing processes, and taking corrective measures to take in your allergen management plan.

Q5: Is there a regulation of allergen management labelling?

A: Yes. The manufacturers of food are obliged to adhere to the local and global labeling regulations, such as the inclusion of priority allergens and precautionary remarks.